When using devices or their accessories, have you longed for a different type of holder, support or other small accessory to make your work easier and to improve practicality or ergonomics? When using the device, do the cables get in the way and risk being caught under the wheels or otherwise getting damaged?

The possible solutions offered by 3D products may positively surprise you, in terms of both quality and price. MedTech-Wessman Oy (3D-Wessman) offers various 3D design and 3D printing services.

By far the biggest advantage of an individually designed 3D product is its adaptability according to its intended use and purpose.

The original model can often be easily modified later if you want to add something more or implement it in a different way.

3D products can be printed in quantities from just one piece to even thousands. In smaller production quantities, the unit price is very moderate compared to other manufacturing methods, for example, separte moulds do not need to be made.

In addition to the material used, the most significant price effect on the final product is the volume and mass of the piece; complexity does not increase printing costs.

”Fist-sized” pieces are roughly around a hundred euros per piece in order lots of a few pieces, but with an order quantity of just a few dozen pieces, the price

per piece may drop almost half. In addition, when manufactured and post-processed with an industrial printer, the product’s durability and appearance stand up to comparison with other manufacturing methods.

In order to achieve a high-quality appearance and versatile colour and post-processing options, I print the final products for my customers with 3D Formtech Oy, a Finnish industrial printing specialist. With their available material options, know-how and printers which represent the latest technology, the end products are sure to be high-quality and durable for different environments.

Despite the use of an external printing service, the product design process, from your first contact to delivery of the product, is carried out on a turnkey basis with MedTech-Wessman Oy.

For product design, I use Autodesk Fusion360 software, which offers high-quality features for design and clear visualisations of the final product.

As a printer for test pieces and printing prototypes, my company has the Creality K1 Max filament printer (FDM), which represents the latest technology.

The print area of the printer is a maximum of 30 x 30 x 30cm. In this way, a physical prototype can be printed quickly and the suitability of the product can be verified, and any necessary changes can be done before printing the final version.

At best, the prototype may be received for testing in just a few days from contact and ideation, with the final products industrially printed usually in a few weeks.

In addition to the different plastics, printing can also be done from aluminium, titanium or tool steel!

You can make a purchase decision after receiving a price estimate and a visual image of the product I have designed.

Getting in touch to bounce around ideas won’t cost you anything yet!

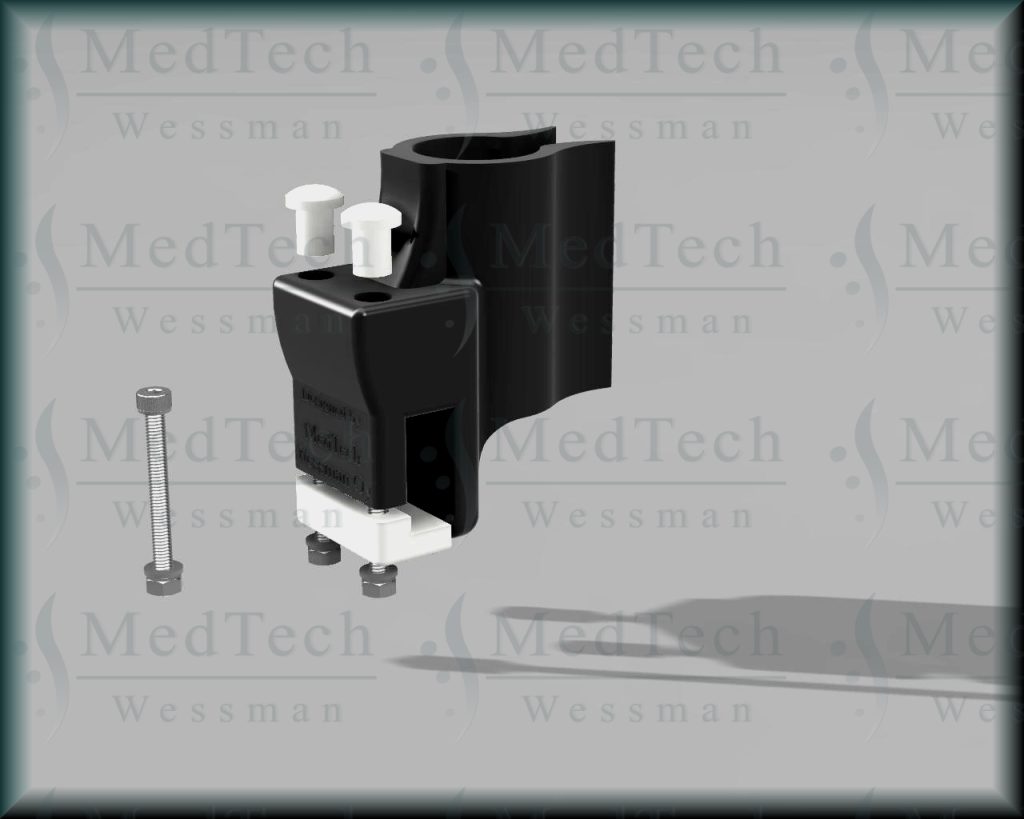

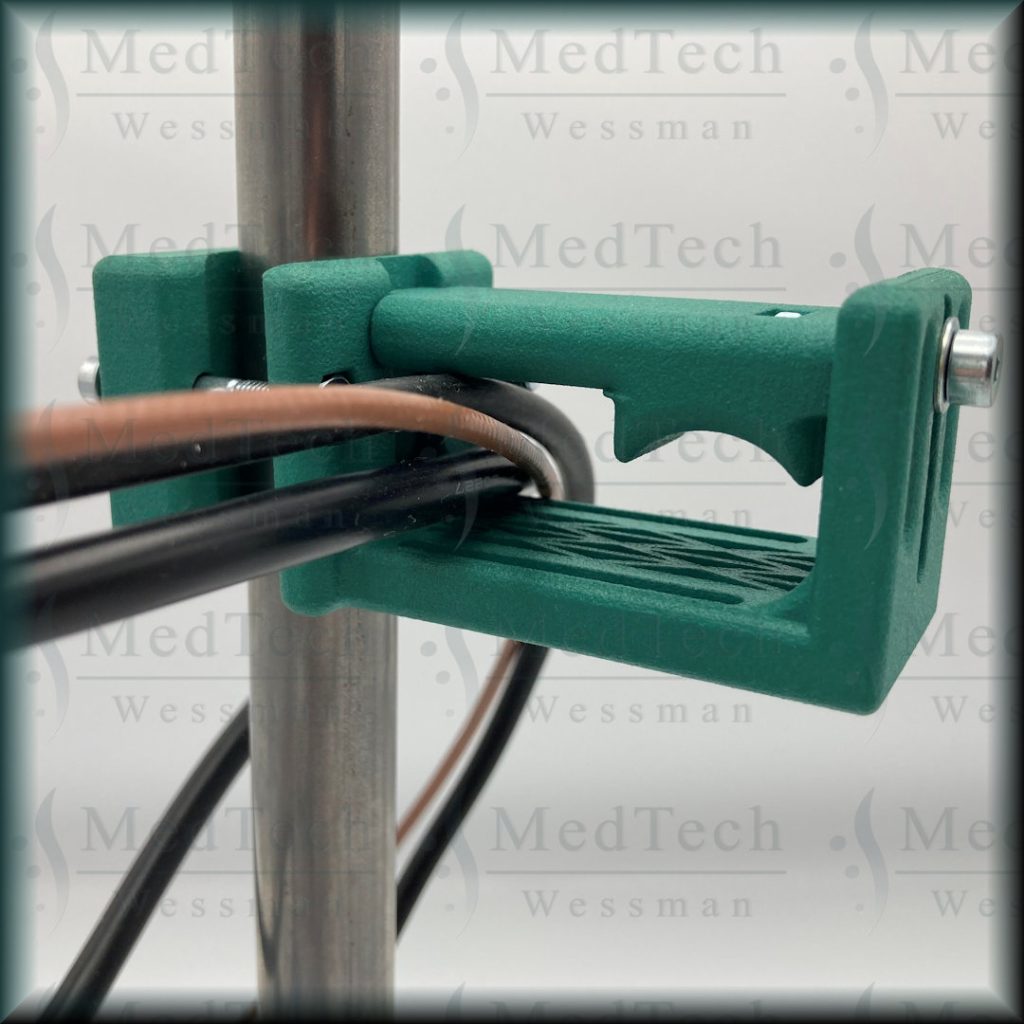

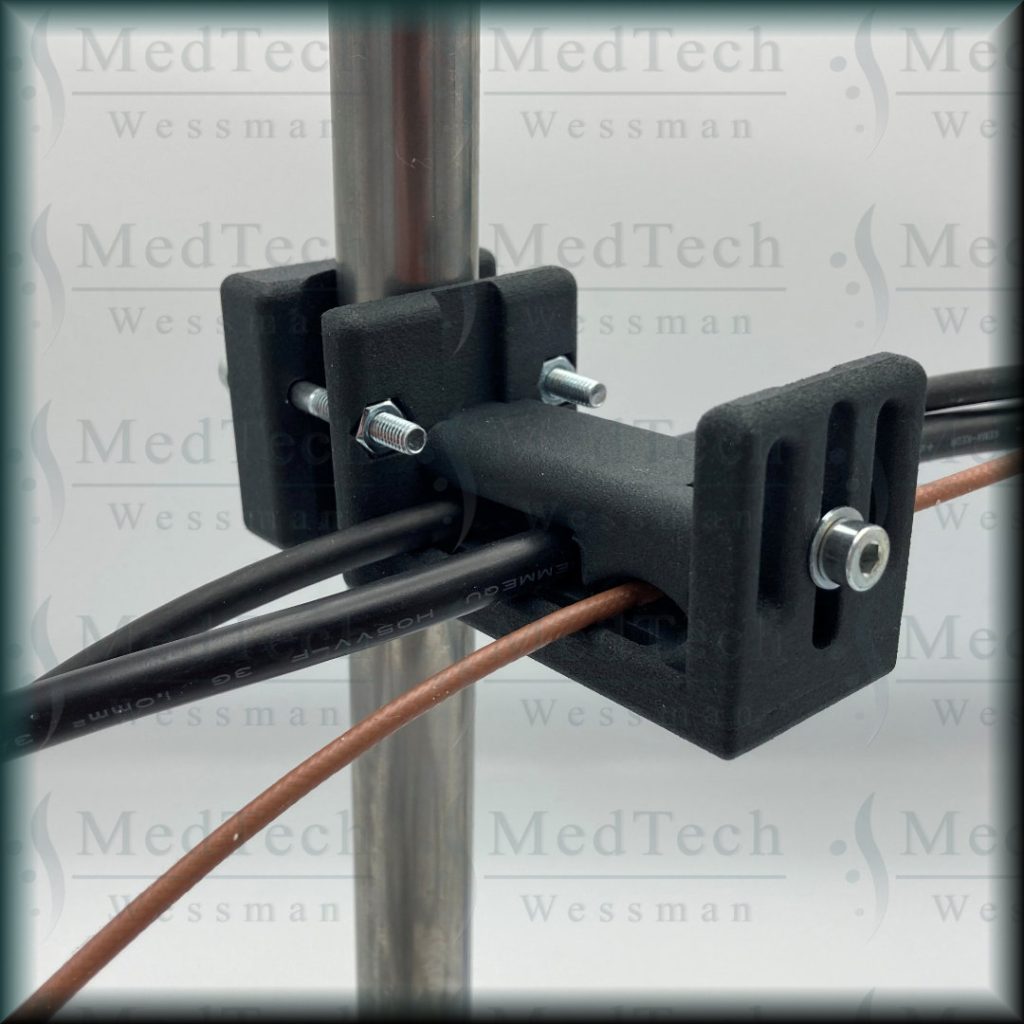

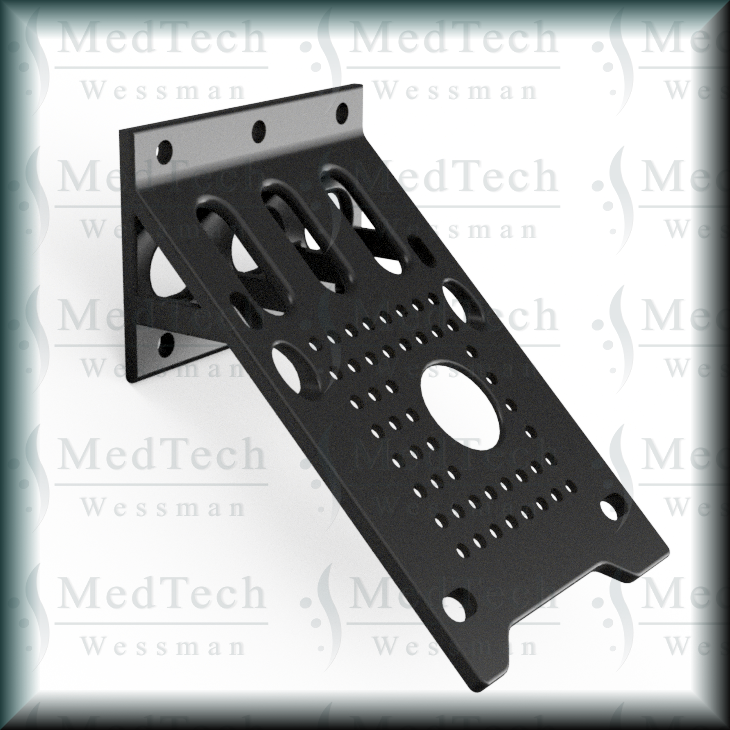

Here are a few 3D products and solutions I have designed.

matching device-specific bracket

(complete)

matching device-specific bracket

(parts separated)

Adjustable clearance

Dyed green (post-processing)

Adjustable clearance

Dyed black (post-processing)

No screw holes or gluing required!

power supply

Wall mounting with screws

measuring head and matching

device-specific bracket